Vacuum deposition systems

Most of our samples are prepared using vacuum methods, i.e., at pressures significantly lower than atmospheric pressure. Currently, our group has 12 vacuum deposition systems available, equipped with planar magnetrons, gas aggregation sources for nanoparticles, or low-pressure evaporation systems. One specialized deposition and analysis chamber is adapted for any deposition with the possibility of measuring the sample during its preparation (e.g., FTIR, ellipsometry) or immediately after its completion without the need to remove it from the vacuum (e.g., XPS).

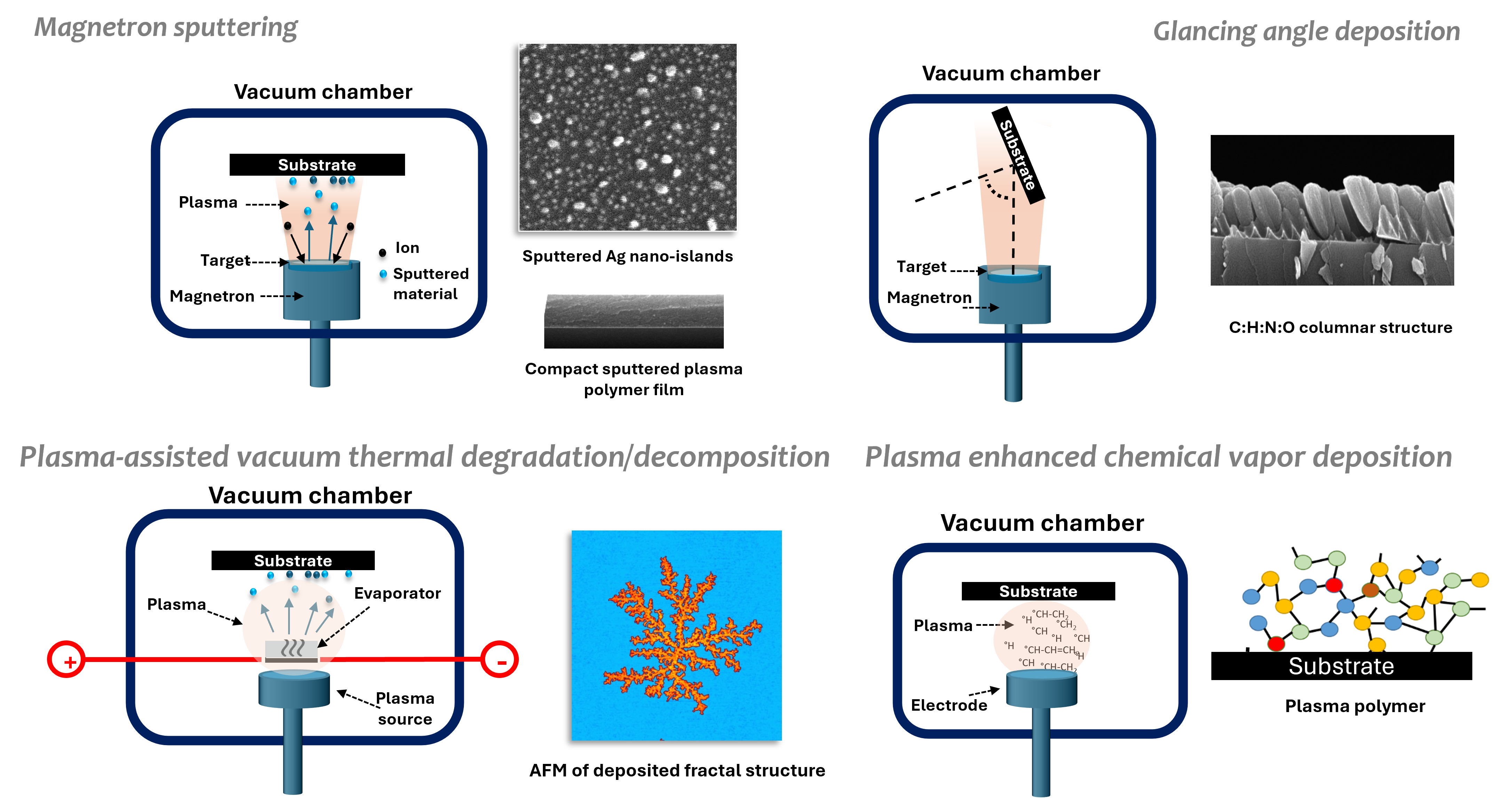

For the actual thin film deposition, several techniques (and their combinations!!) can be used:

- Vacuum evaporation – i.e., Physical Vapour Deposition (PVD).

- Magnetron sputtering.

- Glancing Angle Deposition (GLAD).

- Plasma-Assisted Vacuum Thermal Decomposition (PAVTD).

- Plasma Enhanced Chemical Vapour Deposition (PE-CVD).

Sputtering (vacuum sputtering).

Glancing Angle Deposition (GLAD).

Plasma Assisted Vacuum Thermal Decomposition (PAVTD).

Plasma Enhanced Chemical Vapour Deposition (PE-CVD).