3D printing

3D printing is increasingly establishing itself today as a method for very fast prototyping as well as smaller series production of components. Currently, there are many different types of 3D printers available, allowing printing from a wide range of materials, including plastics, metals, and ceramics. Printers enabling printing with metals or ceramics are still very expensive—in the range of millions of Czech Crowns. In contrast, printers working with polymers are already very accessible, with acquisition costs starting at just a few thousand crowns, and they have very cheap operation. Some of them achieve high manufacturing precision comparable to turned products.

Currently, there are two basic methods for 3D printing from polymers: Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), and Stereolithography Apparatus (SLA). In the first case FFF/FDM, the product is created from a molten polymer that is extruded through a heated nozzle. In the second case (SLA), the object is created by the successive UV polymerization of entire layers from a monomer using a mask formed by an LCD screen.

At KMF, we use printers to produce parts needed for modifications of experimental equipment. Some materials (such as PETG) are highly compatible with vacuum, thus allowing for the quick and inexpensive manufacture of components intended for use inside vacuum chambers. An example is the time-of-flight filter we created for measuring nanoparticle velocity, which was largely printed, and for which another manufacturing method for some components is likely not even possible.

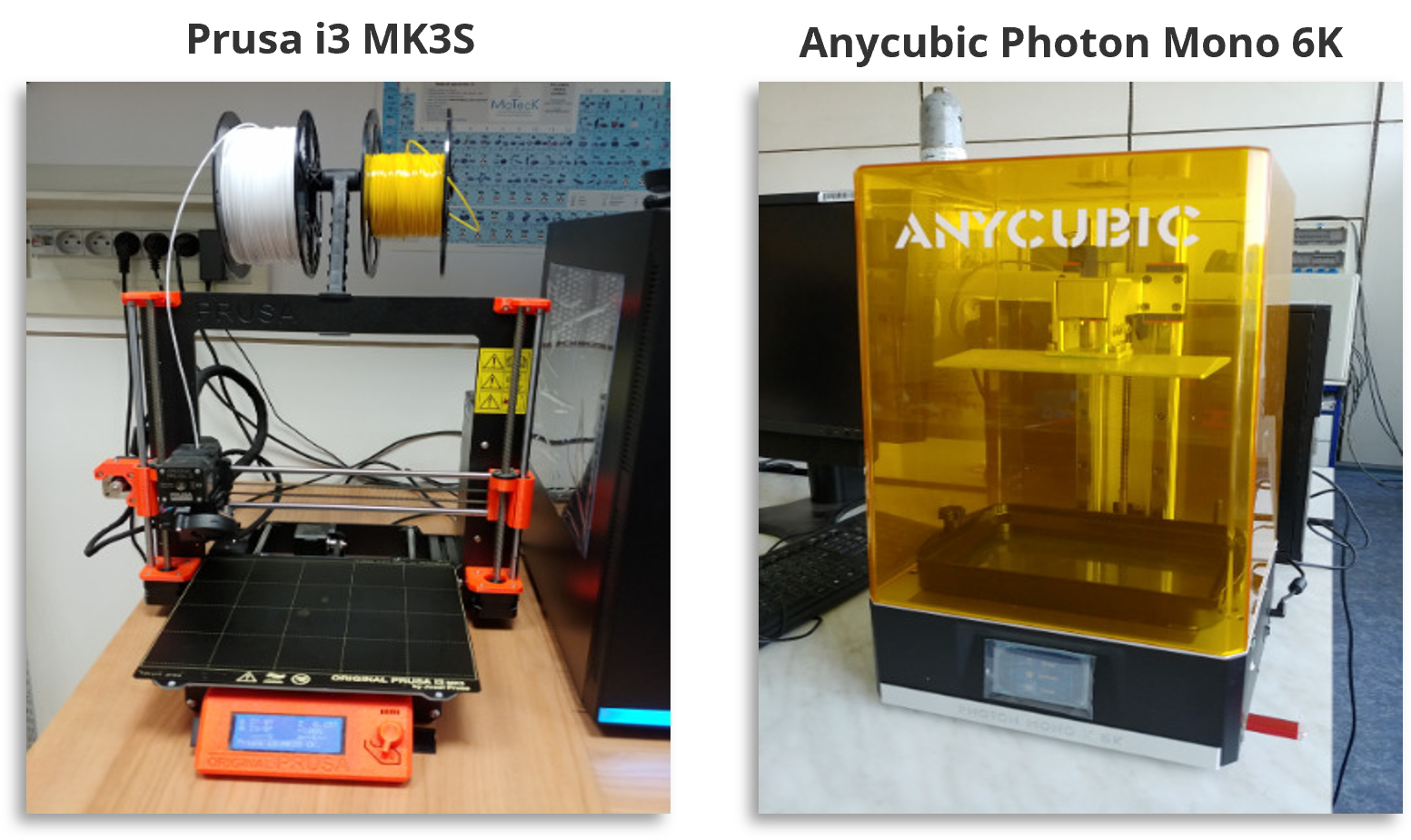

Currently, at KMF, we have both types of 3D printers installed, specifically two Prusa i3 MK3S units, which are among the best currently available within FFF/FDM, and one SLA printer, the Anycubic Photon Mono 6K, with a large printing area (including a washing and curing station).